Chimney Lining

A chimney needs an intact flue liner to meet code and vent the products of combustion. Stainless steel is the most widely used material since it comes in many shapes, sizes and several alloys and the manufacturers do not require any training of the installers. Some of the manufacturers put out some very high quality materials that have held up over the years. We install a lot of stainless steel liners for fireplaces and furnace chimneys.

When the chimney is weak it can be strengthened by installation of a cast in place liner. This method uses an inflatable rubber form. An insulated refractory cement is poured around the form and fills the rest of the chimney. The form is deflated after the cement sets, leaving a new flue.

HeatShield Flue Sealant

Over time the mortar joints between clay flue tiles can deteriorate and leave gaps in the liner. Additionally, the tiles may develop cracks or spalling that leave the chimney unsafe to use. HeatShield® is a ceramic/refractory coating that is pulled up the flue with a winch and a foam applicator plug. This may be used to seal the gaps in the mortar joints or fully coat the surface of the flue tiles.

Thermocrete Lining Systems

When the chimney has badly cracked clay flue tiles that would have to be removed in order to install a stainless steel flue liner we may recommend the use of the Thermocrete system. This involves the spraying of multiple coats of 3000 degree ceramic sealant over the surface of the clay tiles. The Thermocrete is warrantied for life to whoever owns the property. The cost of removing the flue tiles is eliminated and the area of the flue is not significantly reduced.

A thicker application of the Thermocrete material can be applied in chimneys that need internal strengthening. The Thermocrete process is particularly useful in rectangular chimneys where a round stainless steel liner would reduce the flue capacity too much. Factory training is required, assuring a quality job. Both residential and commercial chimneys can be sealed.

Fireplace Restoration

Deterioration in the masonry, cracks in the firebox and smoke chamber, and nearby combustibles can prevent a fireplace from being used safely. These issues should be addressed before the next fire is lit. Joints between the firebrick may need to be repointed with refractory cement. Gaps between the firebox and the face may need to be filled, and the smoke chamber may need to be patched or re-structured.

Sometimes modifications to the fireplace are desired. When a more efficient fireplace is needed, we are able to build a custom Rumford style firebox inside the existing fireplace. A more shallow Rumford style firebox radiates more heat into the room and reduces heat loss up the chimney.

Each side of a Rumford style firebox is the same length and the depth is reduced for better radiation of heat into the room.

Fireplace Interior Anatomy

This illustration shows a (back view) cutaway of a fireplace, smoke chamber, and flue:

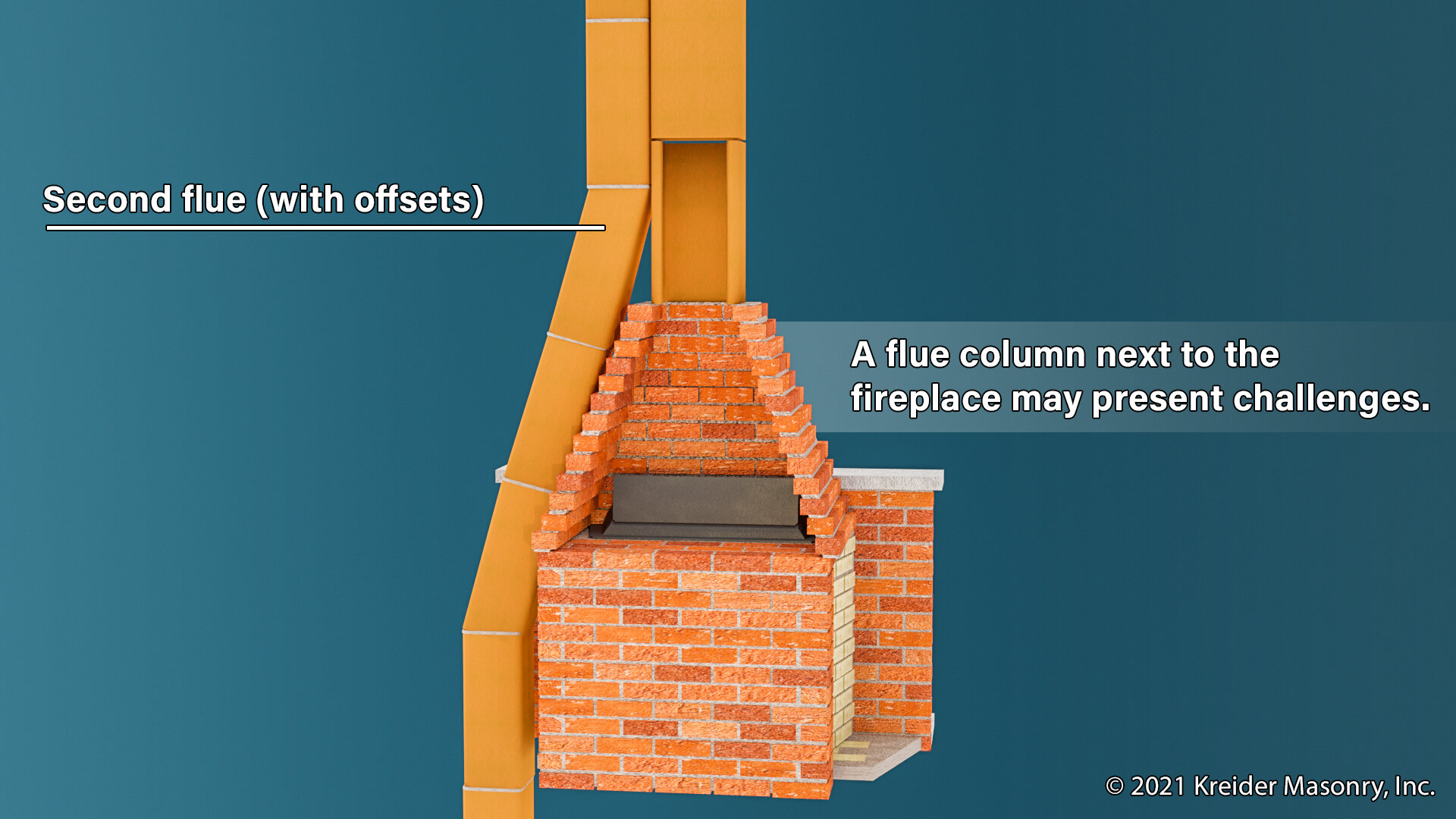

Here’s a fireplace with a second flue column next to it: